Nylon Recoil Air Hose

Manufactured from our flexible nylon tube, our nylon recoil air hose is mainly used in conjunction with air-operated hand tools. The great spring form memory allows the coil and hand tool excellent freedom of motion from the immediate working area.

or call us to discuss your requirements on:

01530 416177

Details

Details

Nylon Air Hoses are commonly used in various industrial applications and have gained significant attention due to their distinct features. These include their: durability, flexibility, and ease of use, to name a few.

ID = Inside diameter

OD = Outer diameter The working pressures of our hose are determined by calculating the short-term burst pressure at 20°C and applying a 4:1 safety factor. The maximum recommended continuous working temperature is 70°C with occasional limited periods of up to 120°C. Any increases in temperature above 20°C will affect the short-term burst pressure quoted. The minimum operating temperature is -40°C.

The Magic of Nylon

Nylon, the first synthetic fibre, was developed in the 1930s. It’s a thermoplastic silky material popular in several industries, from clothing to mechanical parts. This versatility owes to Nylon’s fundamental characteristics, such as its high strength, elasticity, abrasion, and chemical resistance. Most importantly, Nylon can be melt-processed into different shapes, making it an ideal material for products like our Nylon recoil air hose.What is a Recoil Air Hose?

A recoil air hose, or self-storing air hose, is a type of tubing designed to retract back to its compact form when unused. This auto-retraction is beneficial, ensuring the hose remains untangled and easy to store, reducing workplace hazards. This feature, coupled with their lightweight nature, makes recoil air hoses an ideal choice in space-conscious, portable, or mobile applications such as DIY projects, automotive repairs, or industrial machinery.Why Nylon for Recoil Air Hose?

Nylon’s inherent properties make it a suitable material for recoil air hoses. These consist of its:Durability

Nylon is known for its strength and resilience, making it resistant to wear and tear, ensuring the hose’s longevity even under rough conditions.Flexibility

Nylon is remarkably flexible, which means it can be twisted and bent in various directions without breaking. This flexibility is crucial for a recoil air hose, which must regularly expand and retract. The excellent flexibility and coil shape retention make this lightweight air hose ideal for use with air-operated hand tools. It provides superior airflow and is suitable for horizontal or vertical applications. We can also offer a range of polyurethane nylon recoil hoses for extra flexibility. Due to their exceptional abrasion resistance, these hoses are ideal for use in workshop situations.Lightweight

Nylon hoses are typically lighter than their rubber or PVC counterparts, making them more portable and easier to handle.Temperature resistance

Nylon can withstand a wide range of temperatures, which makes these hoses suitable for different environments.Chemical resistance

Nylon is resistant to many chemicals, oils, and solvents, ensuring the integrity of the hose in various working conditions.Features

This type of tubing also has a few other features, such as:- Springform memory and kink resistant

- REACH, RoHS and BSI ISO 9001 resistant

- Abrasion resistant

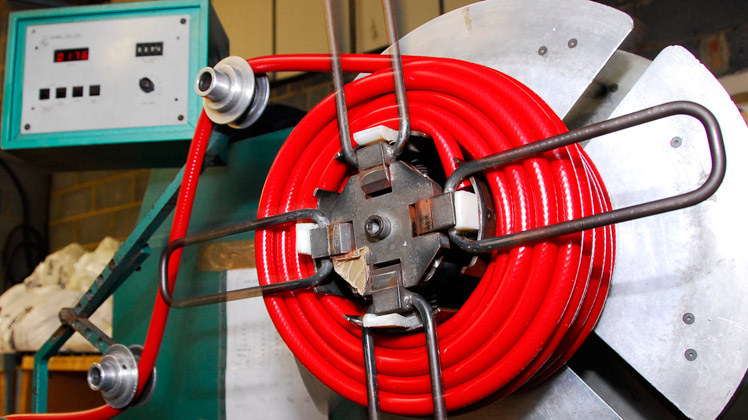

Tube Preforming

We can also offer pre-forming for our range of tubes in various polymers, PVC, Nylon, polythene and polyurethane to suit a wide range of applications. As a result, Pre-forming can reduce costs by eradicating the need for tube fittings.Applications of Nylon Recoil Air Hose

Nylon recoil air hoses are versatile and find applications across various industries due to their durability, flexibility, and resistance to abrasion and chemicals. As a result, Nylon recoil air hoses are used in a variety of applications, including:Pneumatic Tools Operation

Nylon recoil air hoses are widely used in workshops and construction sites to connect pneumatic tools like nail guns, air ratchets, and spray guns to air compressors. Their recoil design helps keep the workspace tidy by automatically retracting to avoid tripping hazards, enhancing safety and efficiency.Automotive Repairs and Maintenance

Mechanics rely on nylon recoil air hoses for operating air-powered tools during vehicle repairs and maintenance. These hoses provide the necessary flexibility and durability for high-pressure air to reach tight spaces in engines and chassis, facilitating tasks such as tyre inflation, engine cleaning, and parts painting.Manufacturing Lines

In manufacturing environments, nylon recoil air hoses are used to power air-driven assembly tools, material handling equipment, and automation systems. Their ability to withstand repeated flexing and exposure to chemicals makes them ideal for the demanding conditions of production lines.Dental and Medical Equipment

The healthcare industry uses nylon recoil air hoses in dental and medical devices for their cleanability and non-toxic properties. They connect air-powered tools used in procedures, ensuring precision and reliability.Aerospace and Aviation Maintenance

Technicians use nylon recoil air hoses in the maintenance of aircraft for powering tools and equipment essential for inspection and repair. Their light weight and flexibility are advantageous in the confined spaces of aircraft fuselages.Painting and Spraying Operations

These hoses are essential in painting and spraying operations, providing a reliable connection between air compressors and spray guns. Their recoil feature helps maintain a clean and organised workspace by minimising loose hose lengths.Food and Beverage Production

Due to their resistance to chemicals and easy cleaning, nylon recoil air hoses are suitable for use in food and beverage production facilities, where they might be used for pneumatic material handling and processing equipment.Laboratories and Clean Rooms

In settings where cleanliness and air purity are crucial, such as laboratories and clean rooms, nylon recoil air hoses are used to connect equipment requiring compressed air, thanks to their resistance to contamination and ease of sanitisation.Agricultural Equipment

Farmers use nylon recoil air hoses with pneumatic tools for equipment maintenance and repair. Their durability and resistance to environmental factors make them suitable for the harsh conditions found in agriculture.Recreational Facilities and Pools

For maintenance and cleaning operations in recreational facilities, including pools and spas, nylon recoil air hoses connect air-powered tools and cleaning devices. Their flexibility and resistance to moisture ensure longevity and reliability in these environments.Pneumatic Tools

The hoses supply compressed air to pneumatic tools in manufacturing, construction, and automotive repair industries.Robotics and Automation

The lightness and flexibility of nylon recoil hoses make them ideal for robotic applications, where weight and freedom of movement are essential.Medical Devices

Specific medical devices use nylon recoil air hoses because of their flexibility, durability, and chemical resistance.DIY Projects

The ease of use and storage make these hoses a favourite among DIY enthusiasts for airbrushing, inflating tyres, or using air-powered tools.Wide Range of Sizes

Our nylon recoil hose comes in a wide range of sizes. The standard nylon recoil hose is black, with other colours available upon request.Endings

We supply all standard recoil hoses with plain ends or include 1/4 BSP swivel taper male fittings and spring guards.Air Tools

We have specifically designed our nylon recoil hose for use with air tools and other air-related equipment, such as drills, sanders, and sprayers. Each of these applications leverages the unique properties of nylon recoil air hoses, demonstrating their versatility and value across a broad range of industries and uses.Technical Information

| Part No. | Coil ID Mandrel | OD | ID | W/L |

|---|---|---|---|---|

| ARA 6/2 | 50mm | 6mm | 4mm | 2.5 metres |

| ARA 6/5 | 50mm | 6mm | 4mm | 5 metres |

| ARA 6/10 | 50mm | 6mm | 4mm | 10 metres |

| ARA 6/10 | 50mm | 6mm | 4mm | 15 metres |

| ARA 8/2 | 75mm | 8mm | 6mm | 2.5 metres |

| ARA 8/5 | 75mm | 8mm | 6mm | 5 metres |

| ARA 8/10 | 75mm | 8mm | 6mm | 10 metres |

| ARA 8/15 | 75mm | 8mm | 6mm | 15 metres |

| ARA 10/2 | 75mm | 10mm | 8mm | 2.5 metres |

| ARA 10/5 | 75mm | 10mm | 8mm | 5 metres |

| ARA 10/10 | 75mm | 10mm | 8mm | 10 metres |

| ARA 10/15 | 75mm | 10mm | 8mm | 15 metres |

Our Nylon Recoil Air Hoses Overall

Nylon recoil air hoses offer an optimal balance between functionality and practicality. Their unique blend of durability, flexibility, and lightweight construction has paved the way for their widespread application in various industries. As technology advances, we can only anticipate more innovative uses for these versatile tools, reinforcing their position as an essential component in the toolkits of professionals and hobbyists alike.Bespoke

Can’t find the right hose to meet your unique requirements?

We have decades of experience in creating custom air hose solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector. Contact us today if you require a bespoke extrusion.

Related Informational Articles about our Nylon Recoil Air Hose

Made to Order Products

Is there a particular specification that you need to be met? We can create a bespoke hose that meets all your requirements and specifications. We work with several businesses regularly to offer the best solution for their needs. Read the examples below to see how we’ve helped several companies solve various problems.