Quality UK Hose & Tube Extrusion Specialists

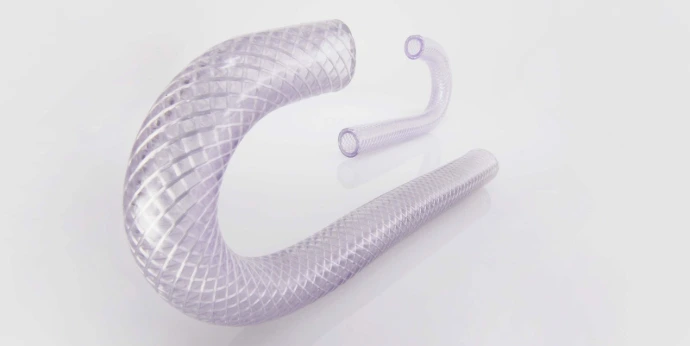

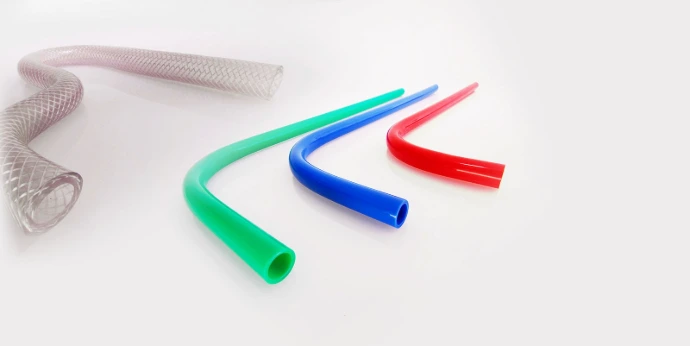

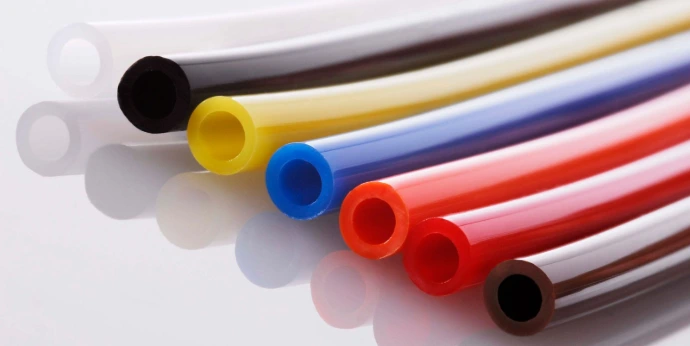

As a UK custom plastic tube extrusion, flexible PVC extrusion, and Nylon extrusion manufacturer, we specialise in both high-volume and low-volume, high-quality product manufacturing for a wide range of hose and tube solutions.

These are suitable for use in numerous industries & applications, from pharmaceutical & beverage production to the hydraulic and pneumatic industry, and we offer competitive prices.

As an expert high-quality plastic tube extrusion manufacturer in the UK, we can extrude a range of materials and plastic profiles for a variety of industries and applications. As a result, we can extrude hose and tube to a wide range of wall thicknesses. With our years of experience, we continue to invest in new technology to meet the ever-changing demands of our customers. Our research and development programme continues to deliver innovative solutions to problems and meet the evolving standards of the extrusion industry. View our hose products, or use our bespoke extrusion page and let us know your specification to manufacture and supply.

01

The extrusion process begins by feeding pellets of PVC compound

into the hopper and heating them until they reach a melted state.

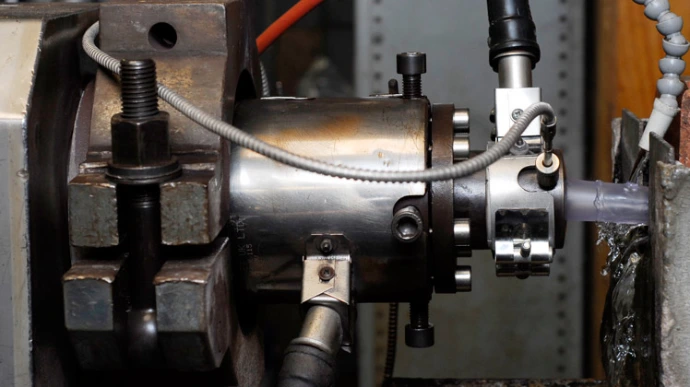

02

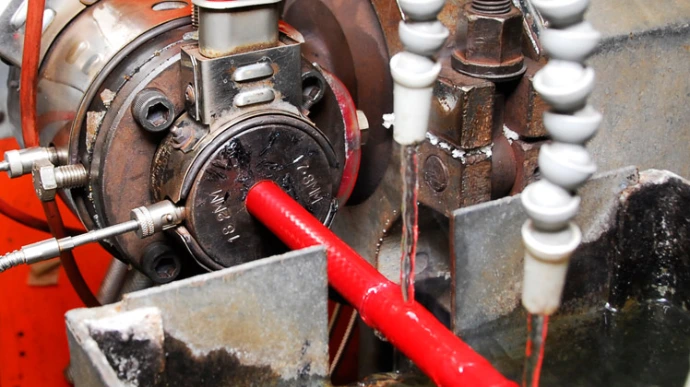

The PVC compound is forced through a die that defines the tube's shape and thickness.

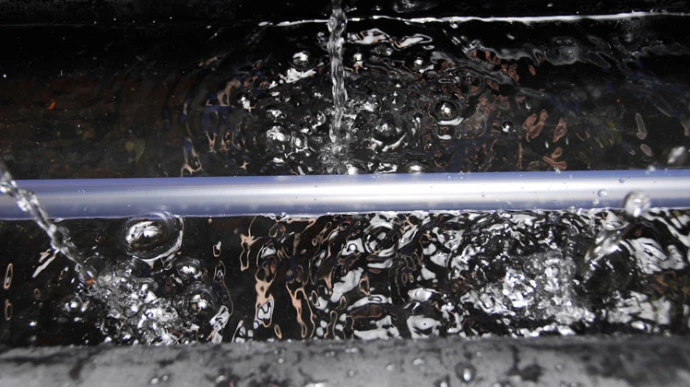

03

The extruded tube is rapidly cooled in a bath of chilled water.

The cool water temperature helps to improve clarity.

04

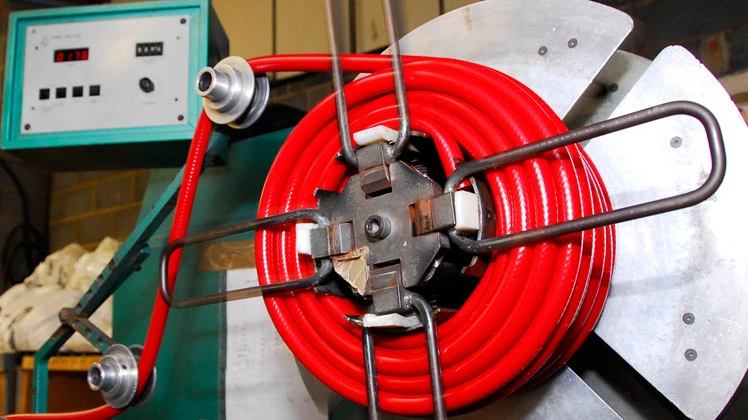

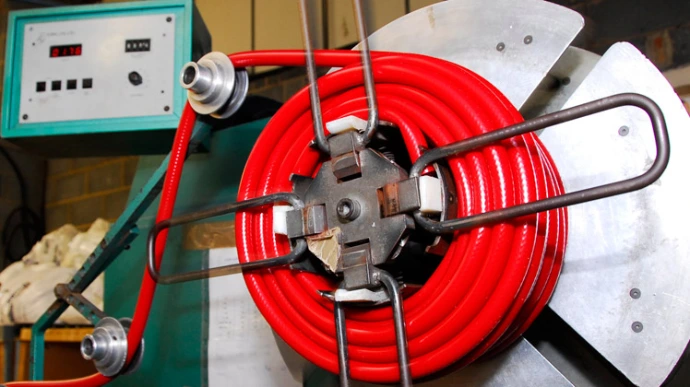

Reinforced polyester twine is now added before the tube is encapsulated again with a protective outer coating.

Custom Plastic Extrusions Hose Specialists

05

06

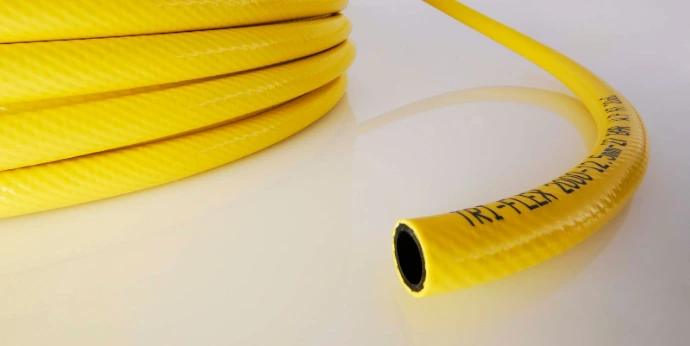

As the tube runs off it is inspected for potential defects and coiled onto reels for packing.

07

Finally, each reel is measured to ensure the tube meets the required inner and outer diameters.

Send us a message

...and we will do our best to get back to you within 48 working hours.

Our Hose and Tube Products...

Meet Our Management Team

The dedicated management team that is behind us.

Bryan Cowan

Chief Executive Officer

Since moving to Leicestershire from Manchester in the early seventies, Bryan has become a stalwart “Blue Army” Leicester City Season Ticket Holder. Bryan is a keen but frustrated golfer still awaiting that perfect par round and a hole-in-one! He is a member of Kilworth Springs Golf Club. Also, he plays golf with many friends and colleagues in the Plastic Industry Golf Society (PIGS).

Good food is paramount to Bryan. His love of good food dates back to his time as a trainee chef. Bryan still delights in cooking today and has attended many varied gourmet training courses to broaden his skill levels. He also appreciates fine wine and pubs with proper people and perfect ales. Bryan enjoys Northern Soul and Motown and attends many eclectic live music events. He also has an appreciation for provincial and West End theatre

Doug Turner

Director

Doug started at Abbey Extrusions as a teenager in 1986. He became a director of the company in 2010.

Outside of work, Doug’s main hobby is scooter racing. He has raced at high speeds on most of the UK’s top circuits and abroad.

Martin Bird

Director

Having studied Engineering at Coalville Technical College, Martin joined Abbey Extrusions in 1986 as a machine operator. Afterwards, he was promoted to Shift Quality Manager and Dispatch Manager before departing for two years to travel around Australia and Southeast Asia.

In 1993, Martin returned to Abbey. In 2007, he was appointed Financial Director and spent three years studying accountancy at Stephenson College. Martin is married with a young family. He spends much of his spare time renovating the family home, but also enjoys trail riding, league pool and karate.

Richard Millington

Director

In 2007, Richard became the company’s works director. His main roles now include production, quality systems, purchasing and personnel responsibility. Richard is also a proud father of two children. With the little spare time he gets, he enjoys photography, gardening and getting stuck into DIY projects.

Rolls of tube produced

500m+

Projects supplied

+30,000

Employees

35

Reoccuring Customers

150,000

What is Thermoplastic tube extrusion?

Thermoplastic tube extrusion can quickly, simply, and easily produce large volumes of tubing and profile products to precise dimensions and tolerances.

This is achieved by using thermoplastic compounded material – usually in the form of pellets – and applying heat, friction and pressure in an extrusion machine.

Once heated to melt, they are then forced through a dedicated die and formers housed within the extruder

machine, this will define their properties, shape, finish and size.

Once the extruded tube, or indeed profile section, has been forced through the die under pressure, its final finished shape is now pretty much defined.

The essential cooling process, executed in strictly dedicated phases, occurs along the entire length of the extrusion cooling bath. This part of the process now plays a crucial role in providing and confirming the exact size and aesthetic finish that complements the overall product quality.

Our reinforced hose, such as our APR range, which is produced with a three-layer, heat and chemically bonded construction with polyester yarn that is woven into the structure between two layers of PVC to provide the vital strength and durability that allows this hose to be used in conjunction with pneumatics systems and also under a very slight vacuum.

What is the purpose of tube extrusion?

The purpose of thermoplastic tubing extrusion is to utilise compounded plastic pelletised material.

This is implemented by forcing and squeezing the heated and melted material through a range of dies and formers to achieve the necessary desired shape and finish.

What industries are plastic tubes ideally designed for?

Plastic hose and tube are key in many industries, including pharmaceuticals, food, beverage, pneumatics, agriculture, construction, hydraulics, automotive, and aerospace to name just a few.

Are extruded hose safe for the food and beverage industries?

The range of hose and tube include: Brewery Hose, Water Hoses, Air Hose, as well as Reinforced PVC Tubing, Clear Flexible PVC Tube, to name a few.

What are typical materials that are extruded?

Nylon and Polyamides of different grades

Can't find the right tube to meet your unique requirements?

We have decades of experience in creating custom tube solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector, so please get in touch today if we can help you with your specific and individual requirements.