Home » News about Abbey Extrusions » The Great Benefits of PVC Tube & Hose

The Great Benefits of PVC Tube & Hose

Resistance

PVC is known for its excellent resistance to a wide range of chemicals, corrosion, and abrasion. These properties make it a reliable choice for applications where durability is crucial. The material withstands exposure to water and various chemical substances, making it suitable for drinking water systems and other fluid transfer needs. Additionally, PVC products resist weathering and rotting, ensuring a long service life in various environments, including piping applications and water pipes.

Flexibility

PVC tubes and hoses provide rubber-like flexibility that’s useful for applications requiring ease of movement or fitting around obstacles. Flexible PVC tubing maintains strength and pliability even at low temperatures, down to approximately -45°C, making it a practical choice for both cold and high-temperature environments. Its flexibility is especially beneficial in plumbing systems and in industries requiring adaptable fluid transfer solutions.

Flow Visibility

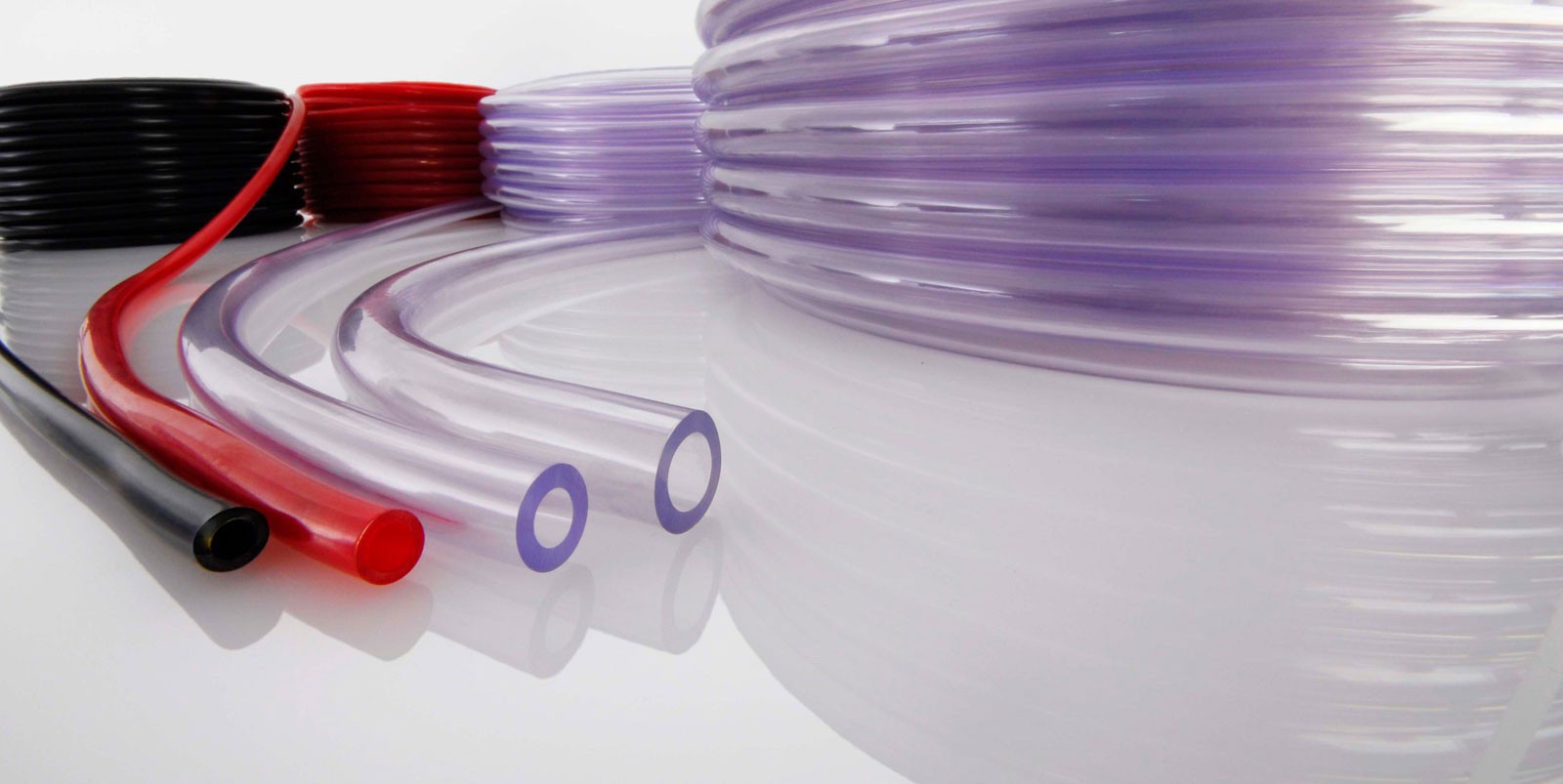

Clear PVC tubing offers excellent visibility for monitoring water flow, which is particularly useful in food, pharmaceutical, and chemical industries. This transparency makes PVC an ideal option for processes that need visual checks to ensure smooth operation, reducing the risk of blockages and improving overall efficiency.

Versatility

PVC’s versatility is unmatched, as it can be moulded into numerous forms, colours, and designs to suit a wide range of applications. From medical and food-grade hoses to industrial chemical-resistant tubes, PVC caters to a wide variety of needs. PVC piping, for instance, is widely used across industries, from health and safety applications in the food industry to flexible hoses for air and water flow systems.

Health and Safety

With a well-researched history, PVC meets international standards for health and safety, making it a reliable choice in sensitive applications, such as potable water and food-grade hose systems. PVC’s inert and stable properties ensure it won’t impart odours or tastes to the substances it transports, making it highly suitable for the food and beverage industries and drinking water applications.

Stability

As an inert polymer, PVC maintains stability when in contact with various liquids, preventing contamination or unwanted chemical reactions. This characteristic is key for uses in the pharmaceutical industry, such as medical applications, chemical processing, and situations requiring safe, reliable fluid transfer. PVC’s durability and chemical corrosion resistance make it an ideal material for high-quality, low-maintenance systems.

Cost-Effectiveness

It is also very cost-effective, which is due to PVC – being one of its most appealing benefits. PVC hoses and pipes require minimal maintenance cost, reducing long-term costs compared to other materials, such as cast iron. PVC’s low cost, combined with its long lifespan, makes it a wise choice for both small and large-scale projects.

Choosing the Right PVC Product

Selecting the right PVC tube or hose for a specific purpose is essential to ensure maximum benefit. At Abbey, we offer a wide range of PVC products and can help guide you in choosing the best option for your needs, whether it’s for a plumbing system, flexible hose, or chemical-resistant application. Our expert sales team is here to provide advice and answer any questions.

More About PVC

What is PVC?

Polyvinyl Chloride (PVC) is a versatile, durable thermoplastic known for its chemical resistance, abrasion resistance, and resistance to corrosion. By adding plasticisers, PVC can be made more flexible, allowing for a variety of applications in flexible tubing and piping.

Uses of PVC Tubes and Hoses

PVC tubing is used in plumbing, medical, and industrial applications, with flexibility and chemical resistance being key advantages. It’s ideal for transporting fluids, gases, and even solids, making it highly valued across numerous applications.

Manufacturing Process

PVC tubes are produced through extrusion, where melted PVC resin is shaped and cooled. Additives can adjust properties like flexibility and temperature resistance, creating options such as temperature-resistant Air Hoses and flexible PVC hoses.

Difference Between PVC and CPVC

Chlorinated PVC (CPVC) offers higher temperature resistance, making it more suitable for hot water systems, whereas standard PVC is preferred for cold water and general applications.

Environmental Considerations

PVC is durable and has a long life, which can reduce waste. Recycling PVC, while complex, is possible and can help mitigate environmental impact.

High-Pressure Capability

PVC can handle moderate to high pressures depending on its thickness and construction, ideal for applications like water supply and compressed air systems.

PVC Tubes for Potable Water

Certain PVC hoses are certified safe for drinking water, meeting health and safety standards for potable applications and ideal for things such as PVC hose pipes due to the fact that they have next to no water loss due to their excellent abrasion properties.

Temperature Impact

PVC tubes may become brittle in the cold and soften in heat. Choosing the right PVC type for the environment ensures optimal performance.

Cutting and Joining PVC Tubes

PVC can be easily cut and joined using PVC cement or threaded fittings for a strong, leak-free connection.

Lifespan

PVC has a long service life, often exceeding 50 years, though environmental factors may influence longevity.

Chemical Resistance

PVC is generally resistant to many acids, bases, salts, aliphatic solutions, and oxidising agents. However, it can be damaged by some solvents, chlorinated hydrocarbons, and aromatic compounds. Always check the chemical compatibility for specific applications.

Underground Use of PVC Tubing

PVC is commonly used for underground pipes due to its strength and resistance to corrosion and chemicals. However, proper installation and protection against physical damage are crucial.

PVC Hoses for Air or Pneumatic Systems

PVC hoses can be used for pneumatic systems thanks to their suitability for main PVC fittings, but ensuring they are rated for the system’s specific pressure and temperature conditions is essential. Please note, that specialised air hoses made of PVC are also available for this purpose.

the system’s specific pressure and temperature conditions are essential. Specialised air hoses made of PVC are available for this purpose.

Benefits of PVC Pipes Closing Thoughts

As you can see PVC tubes and hoses offer you a very reliable and cost-effective solution for a wide range of applications, from household plumbing to complex industrial systems.

With exceptional resistance to chemicals, corrosion, and temperature variations, PVC products deliver long-lasting performance while maintaining health and safety standards. Whether you need durable tubing for potable water, flexible hoses for airflow, or specialised piping for chemical resistance, PVC remains a trusted choice across numerous industries.

Consequently, our expert sales team is here to help you choose the right PVC tube or hose for your specific needs if you are not sure. Just contact us today to explore how PVC can enhance your systems, providing you with the durability and peace of mind for years to come that using PVC pipes brings.

Bespoke

Can't find the right tube to meet your unique requirements?

We have decades of experience in creating custom tube solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector.