Abbey Extrusions

Quality UK Hose & Tube Extrusion Specialists

As a UK custom plastic tube extrusion, flexible PVC extrusion, Nylon extrusion manufacturer, we specialise in both high volume & low volume quality product manufacturing to a wide range of hose and tube solutions.

These are suitable for use in numerous industries & applications, from pharmaceutical & beverage production to the hydraulic and pneumatic industry and we offer competitive prices.

Bespoke

Special projects and precise specifications are easily met with our bespoke extrusion service.

Pelmets

Special projects and precise specifications are easily met with our bespoke extrusion service. Learn more about our HGV PelmetsCustom Plastic Extrusions Hose Specialists

As an expert high quality plastic tube extrusion manufacturer in the UK, we are able to extrude different materials and plastic profiles for a range of different industries and applications. As a result we can extrude hose and tube to a wide range or wall thicknesses.

With our years of experience we continue to invest in new technology to meet the ever-changing demands of our customers. Our research and development programme continues to provide innovative new ways to solve problems and meet the evolving standards of the extrusion industry.

View our hose products, or use our bespoke extrusion page and let us now your specification to manufacture and supply.

Featured Products

What are 5 Benefits of Fluted Water Hose?

Fluted water hoses tough hoses designed and developed for conveying water in a number of applications - due to the benefits listed below - such as:

Garden

Agricultural sites, and for use in fields Construction and building sites. It is typically available in lengths of 40m and 100m; however, we are able to manufacture custom orders should you require a different length. How is this type of hose typically manufactured?

This heavy duty water hose is...

Our Manufacturing & Extrusion Process

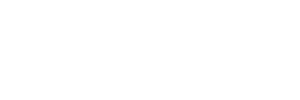

Hose & Tube Extrusion Stage 1

The extrusion process begins by feeding pellets of PVC compound

into the hopper and heating them until they reach a melted state.

Hose & Tube Extrusion Stage 2

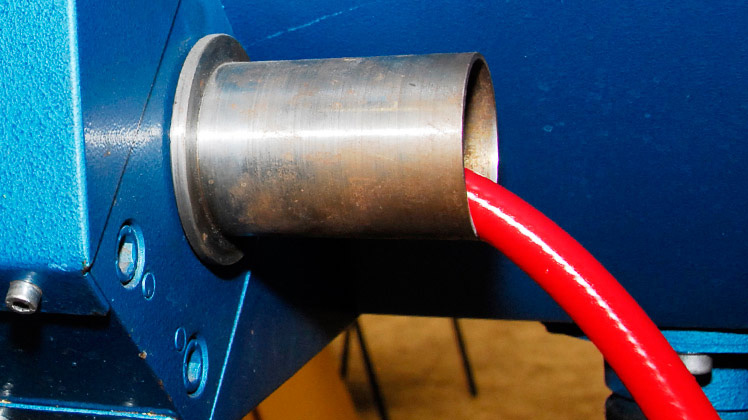

The PVC compound is forced through a die that defines the shape and thickness of the tube.

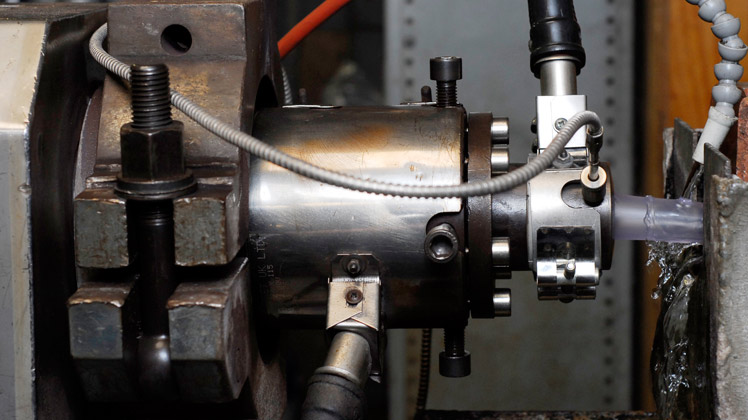

Hose & Tube Extrusion Stage 3

The extruded tube is rapidly cooled in a bath of chilled water.

The cool water temperature helps to improve clarity.

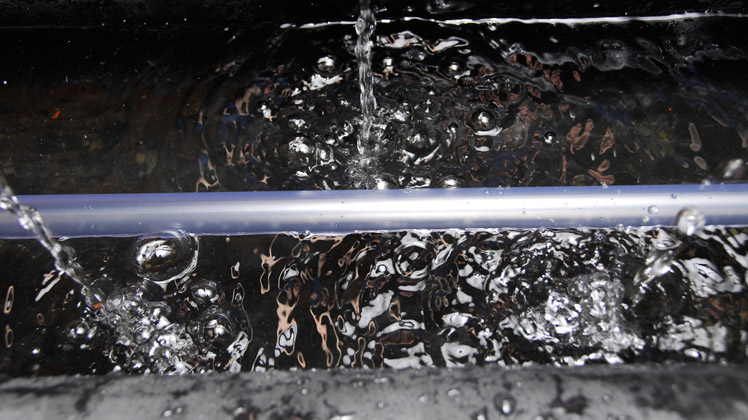

Hose & Tube Extrusion Stage 4

Reinforced polyester twine is now added before encapsulating

the tube again with a protective outer coating.

Hose & Tube Extrusion Stage 5

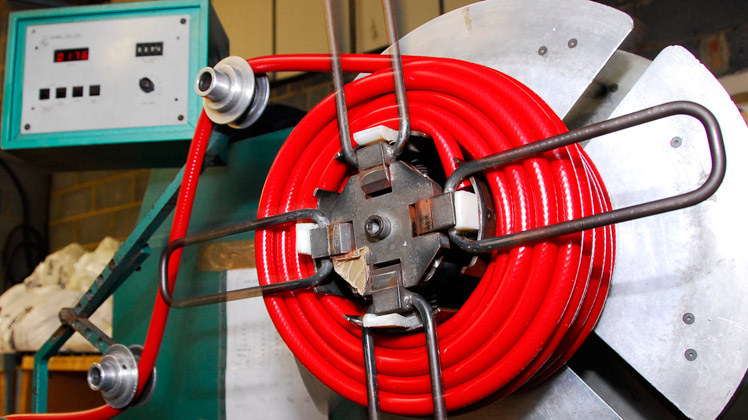

Rollers pull the tube through the entire process and cut it into required lengths.

Hose & Tube Extrusion Stage 6

As the tube runs off it is inspected for potential defects and coiled onto reels for packing.

Hose & Tube Extrusion Stage 7

Finally, each reel is measured to ensure the tube meets the required inner and outer diameters.

What is Thermoplastic tube extrusion?

Thermoplastic tube extrusion can quickly, simply and easily create a large volume of tubing and profile products to precise dimensions and tolerance.

This is achieved by using thermoplastic compounded material – usually in the form of pellets – and adding the inclusion of heat, friction and pressure within an extrusion machine.

Once heated to melt, they are then forced through a dedicated die and formers housed within the extruder

machine, this will define their properties, shape, finish and size.

Once the extruded tube or indeed profile section has been forced through the die, under pressure its final finished shape is now pretty much defined.

The essential cooling process, which is executed in strict dedicated phases, along the entire length of the extrusion cooling bath. This part of the process now takes on a crucial role in providing and confirming the exact size and aesthetic finish that compliments the overall product quality.

Our reinforced hose, such as our APR range , which is produced with a three layer, heat and chemically bonded construction with polyester yarn that is woven into the structure between two layers of PVC to provide the vital strength and durability that allows this hose to be used in conjunction with pneumatics systems and also under a very slight vacuum.

What is the purpose of tube extrusion?

The purpose of thermoplastic tubing extrusion is to utilise compounded plastic pelletised material.

This is implemented by forcing and squeezing the heated and melted material through a range of dies and formers to achieve the necessary desired shape and finish.

What industries are plastic tubes ideally designed for?

Plastic hose and tube are key in many industries, including pharmaceuticals, food, beverage, pneumatics, agriculture, construction, hydraulics, automotive, and aerospace to name just a few.

Are extruded hose safe for the food and beverage industries?

Yes. This is all determined by the type and grade of the compounded PVC materials that are used in the extrusion process.

In this instance we will use different specialist types of materials that do not leach any toxic chemicals after production construction that emit any nasty taste, odours, or be environmentally or medically unsafe to pass liquids, powders, granules or gases through them.

All these types of tubes are tested and comply with stringent UK Health and Safety Regulations, and are classed as food and drink safe to use.

The range of hose and tube include: Brewery Hose, Water Hoses, Air Hose, as well as Reinforced PVC Tubing, Clear Flexible PVC Tube, to name a few.

What are typical materials that are extruded?

Typical plastic materials that we use in our extrusion process can include:

- Polycarbonate

- Rigid PVC

- Polyethylene (PE)

- Polypropylene

- Polyurethane

- Polyvinyl chloride (PVC)

- Nylon and Polyamides of different grades

Can't find the right tube to meet your unique requirements?

We have decades of experience in creating custom tube solutions for a wide range of industries, ranging from the pharmaceutical industry to the aeronautics sector, so do please get in touch today if we can help you with your specific and individual requirements.